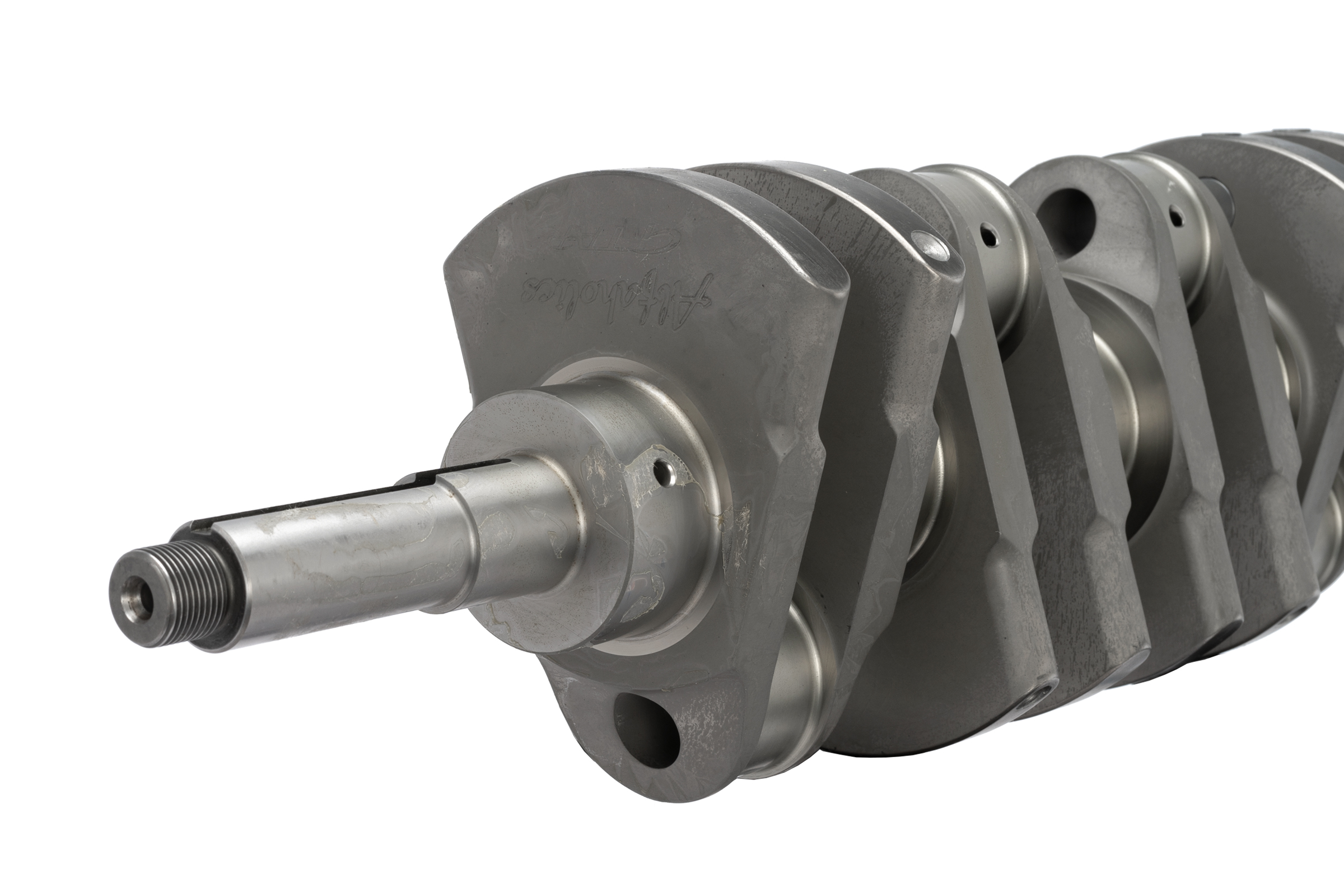

Crankshaft • Long Stroke • 2000 Nord & Twin Spark

ENG3431

£4,995.00 GBP (ex vat)

The Alfaholics-R parts badge is reserved for the finest quality components developed to offer ultimate performance.

Product Information

Designing from scratch using modern knowledge of optimum crank design and CAD to optimise the crank for 2000 Nord and Twin Spark engines.

The stroke of the crank is stretched to the maximum whilst ensuring it fits the block without modifications, increasing it by 5.5mm to 94mm, which gives just over 2100cc with 84.6mm bore, or just under 2300cc with 87mm bore.

Our development engine has produced 15BHP extra versus an original. Resulting in Twin Spark engines producing 230-240BHP and Nord engines producing 220-230BHP.

Conscious to remove any weight where necessary, with the big ends specially bored hollow to reduce centrifugal weight. The counterweighting has been optimised with very specifically shaped and sized webs to ensure perfect piston & rod counterweighting at high revs. The result is a long stroke, increased capacity crankshaft that revs up faster and is more free revving than a factory crankshaft.

After the billets are turned they undergo a stabilising process where they are reheated and left to cool, this removes any of the machine stresses and further improves the qualities of the material, once the cranks are finished milling they undergo an internal rumbling process that deburs the machined surfaces and also assists with further destressing of the material.

Crankshafts are pre and post-nitride CNC ground for accuracy and control of journal sizes as well as nitriding case depth uniformity. Gas nitride hardening achieves a bearing surface hardness up to 900 Hv to approx. 0.5mm.

What’s Included

Long Stroke Crank

Quantity: 1

Needle Roller Spigot Bearing

Quantity: 1

Upgrades & Additions

Monza Piston & Rod Set

Quantity: 4 (1 Set)

Technical Details

Brands

Alfaholics-R

Application

Fast Road

Track Day

Competition

Quality

Alfaholics-R

Compatibility

Nord

2000

Twin Spark

8V Engine

Material

Steel

EN40B (722M24)

Finish

Nitration

Weights

Total

18.5kg

Feature

Details

Material Grade: T Condition 850 – 1000 N/mm2 24 – 31 HRC

Benefits

Extra 5.5mm stroke

Systems

Engine

Engine

Crankshaft

Nord

Twin Spark

Compatible Models

| Model | Year(s) | Engine & Body | Reference |

|---|---|---|---|

| 2000 Berlina 105.12 / 105.15 | 1971-1975 | 1962 4 Door Saloon | Berlina |

| 2000 Berlina USA 115.00 | 1971-1975 | 1962 4 Door Saloon | Berlina |

| 2000 GTV 105.21 / 105.22 | 1972-1977 | 1962 2 Door Coupe | Flat Front GTV, Bertone |

| 2000 GTV USA 115.01 | 1972-1977 | 1962 2 Door Coupe | Flat Front GTV, Bertone |

| 2000 GTV SE 105.22 | 1978-1979 | 1962 2 Door Coupe | GTV SE, Special Edition, Bertone |

| 2000 Spider Veloce 105.24 / 105.27 | 1972-1982 | 1962 2 Door Convertible | S2, Kammtail, Coda Tronca |

| 2000 Spider Veloce USA 115.02 | 1972-1982 | 1962 2 Door Convertible | S2, Kammtail, Coda Tronca |

| 2000 Spider Veloce 115.66 | 1983-1989 | 1962 2 Door Convertible | S3, Kammtail, Aerodynamica |

| 2000 Spider Graduate 115.66 | 1983-1989 | 1962 2 Door Convertible | S3, Kammtail, Aerodynamica |

| 2000 Quadrifoglio Verde 115.60 | 1983-1989 | 1962 2 Door Convertible | S3, Kammtail, Aerodynamica, QV |

| 2000 Spider 115.A1 | 1990-1994 | 1962 2 Door Convertible | S4 (sometimes Kammtail) |

| 2000 Spider Veloce 115.A1 | 1990-1994 | 1962 2 Door Convertible | S4 (sometimes Kammtail) |

| 1750 GTAm 105.51 | 1969 | 1998 2 Door Coupe | |

| 2000 GTAm 115.01 | 1972 | 1998 2 Door Coupe | |

| Alfetta 2.0 116.55 / 116.55 | 1977-1984 | 1962 4 Door Saloon | |

| Giulietta 2.0 116.A1A / 116.A1A | 1980-1985 | 1962 4 Door Saloon | |

| Giulietta Turbodelta 116.A1A | 1984-1985 | 1962 4 Door Saloon | |

| GTV 2.0 116.36 / 116.36 | 1980-1987 | 1962 2 Door Coupe | GTV, Alfetta |

| Turbodelta GTV | 1979-1980 | 1962 2 Door Coupe | |

| 75 2.0 161 | 1985-1988 | 1962 4 Door Saloon | |

| 75 Twinspark 162B / 162B | 1988-1992 | 1962 4 Door Saloon | |

| Veloce 162B / 162B | 1988-1992 | 1300 4 Door Saloon | |

| 75 Twinspark LE 162B / 162B | 1991-1992 | 1962 4 Door Saloon | LE, ASN, Numerata |

| 90 2.0 162A | 1984-1987 | 1962 4 Door Saloon | |

| 164 Twinspark 164 / 164 | 1988-1994 | 1300 4 Door Saloon | |

| 155 2.0 TS 167 / 167 | 1992-1995 | 1995 4 Door Saloon |