Product Information

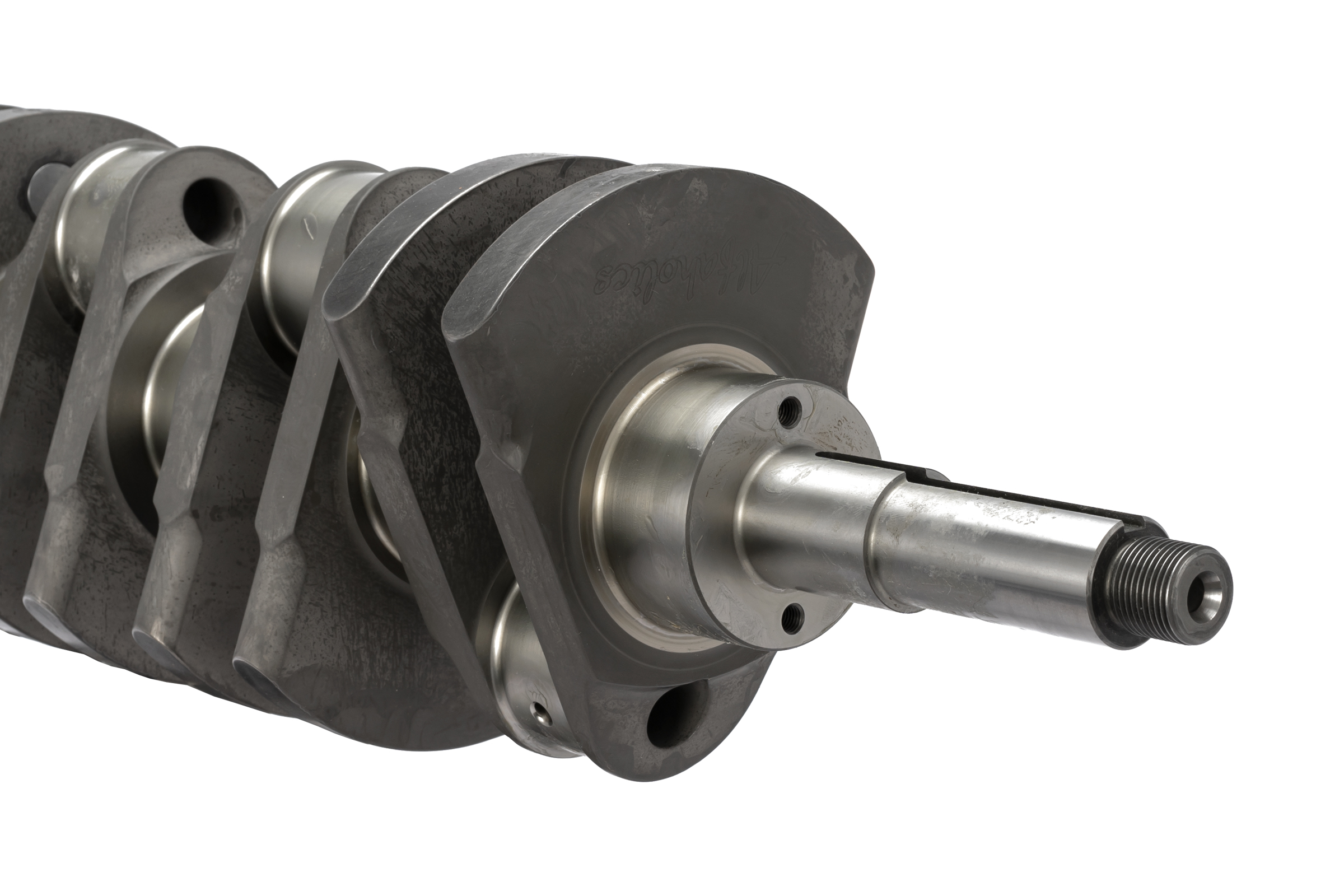

Designed from scratch using modern understanding of counterweighting, oil gallery design, material specification and surface treatments to radically improve performance over a factory crankshaft, thereby removing all the original crank’s design flaws. It is the inadequate counterweight design and poor oil gallery design of an Alfa crank that is the cause of all big end bearing failures on performance 1600 engines using factory cranks, these failures are typically seen as a seizing of no.4 big end bearing and resultant rod failure.

Our new crank has an 8 counterweight design with very specific placement of the counterweight mass, this results in significantly improved smoothness at high revs due to the piston & rod assembly being optimally counterweighted whilst also ensuring a very free revving engine characteristic.

This allows the engine to be revved higher to produce more power with greatly increased reliability, this crank is regularly run to 8,800 rpm. The oil gallery route has also been optimised to provide vastly superior lubrication of the bearings when most required in the cycle which means that more oil is delivered to the bearing and less oil pressure required to deliver the flow rate thus reducing power losses.

The original ‘half moon’ system for locating the flywheel bolts has been replaced with direct threading of the crank using M10 bolts for improved strength. The crank is supplied balanced, and finished with a nitride coating.

After the billets are turned they undergo a stabilising process where the billets are reheated and left to cool, this removes any of the machine stresses and further improves the quality of the material, once the cranks are finished milled they undergo an internal rumbling prices that deburrs the machined surfaces and also assists with further de-stressing of the material.

Crankshafts are pre and post nitride CNC ground for accuracy and control of journal sizes as well as nitriding case depth uniformity.

Gas nitride hardening achieves a bearing surface hardness up to 900 Hv to approx. 0.5mm.

What’s Included

1600 Race Crankshaft

Quantity: 1

Technical Details

Brands

GTA-R

Quality

Alfaholics-R

Finish

Nitration

Weights

Total

17.4kg

Material

Steel

722M24 (EN40B Aerospace Grade)

Feature

Details

Superior Oil Gallery Design

Models

All 105 / 115 Series

Compatibility

Engines

1600 Nord engine